Engineering department

Engineering department

Specialists with work experience, capabilities and the ability to implement tasks of any complexity are gathered in the engineering department

Opportunities:

- design engineering of parts, structures and systems of a high degree of complexity in the metallurgical industry, the field of mechanical engineering;

- development of design documentation, with compliance with all design stages in accordance with SSU and ESKD and customer requirements;

- individual design, standard design;

- execution of technical calculations;

- execution of working drawings of parts and components of equipment according to sketches;

- performing measurements and sketches of failed units and parts in the conditions of the customer’s workshop on site, with partial disassembly of the failed equipment according to existing parts;

- processing of the customer’s drawings (checking, finalizing), working with foreign drawings and foreign standards;

- development of the product for manufacturability;

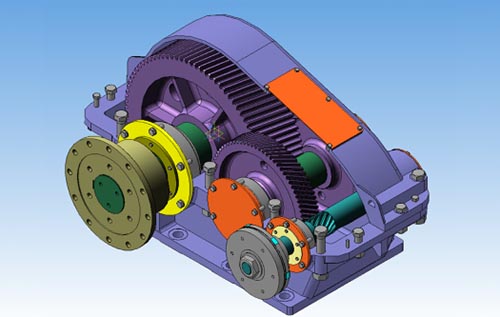

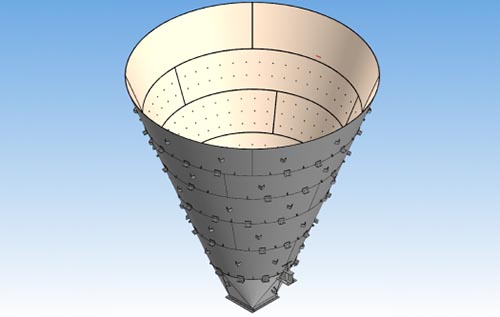

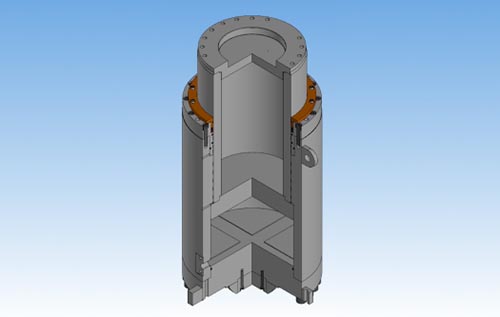

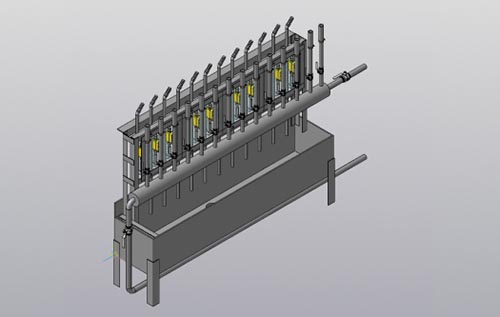

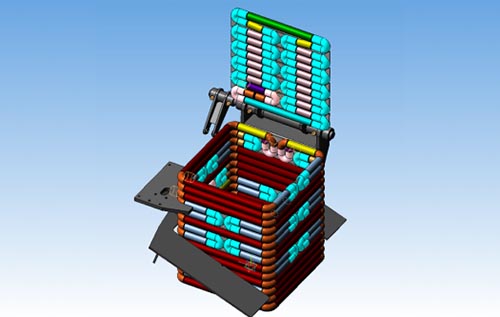

- 3D modeling and visualization;

- development of technical solutions for the repair of metal structures of cargo-lifting cranes;

- development of design documentation for the manufacture of cargo handling devices;

- development of design documentation for the manufacture of parts of pneumatic and hydraulic equipment, development of schematic diagrams of connections;

- development of load-transport schemes, container drawings of manufactured parts and assemblies for external customers;

- development of non-standard equipment and devices in connection with reconstruction of objects, automation of production and mechanization of labor-intensive processes. Carrying out works to increase the level of unification, standardization and certification of designs of the products being developed;

- development of design documentation for the production of metal constructions in the workshops of the LLC “CMP”;

- design of technological equipment;

- design of press forms and stamps;

- designing foundry equipment;

- canning of sheet metal products (for bending, stamping);

- development of drawings for welding and surfacing works;

- development of typical and non-standard means of automation and mechanization of production processes, drive control schemes using microprocessor and frequency equipment;

- author support of designed products at the stages of design, technological preparation, manufacturing, implementation and operation.

Key values:

- Knowledge of the production technology in the places of integration of the products being developed, the needs of the customer, the technology of manufacturing the product, issues of OD and PB.

- Orientation to the result, which is expressed in accumulated experience, deep knowledge, reasonableness of actions and decisions made.

- Innovation, based on the prompt use of new developments, the use of modern development environments and design methods.

- Responsibility, which is understood as professionalism in one’s field, adequacy in assessing tasks and the ability to rationally use resources.

- Work in a team, including qualities such as ambition, a proactive and positive approach and a caring attitude.

- High speed of development of design documentation – on-site visit – assessment of the degree of complexity – decision-making – coordination with the customer – drawing creation, from 1 day.

- Versatility, simultaneous work with many directions.

- Development of design documentation directly under the customer.

- Flexibility, making adjustments in the design process at the customer’s request.

- A large archive of design documentation of developed products.

- Prompt resolution of issues arising during installation of manufactured equipment at the installation site.

The design engineering department develops design documentation for the execution of external orders for enterprises of Ukraine and foreign countries: Mexico, Slovakia, Romania, France, Hungary, Algeria, Bosnia and Herzegovina, Kazakhstan.

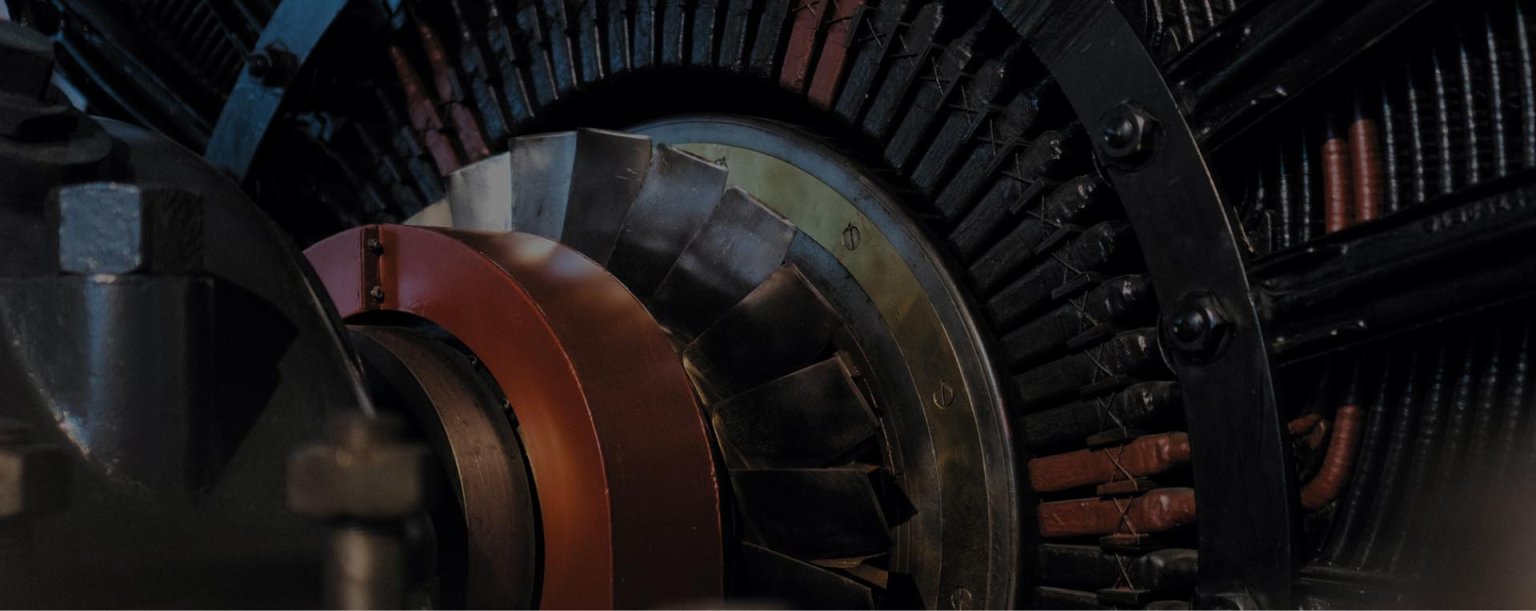

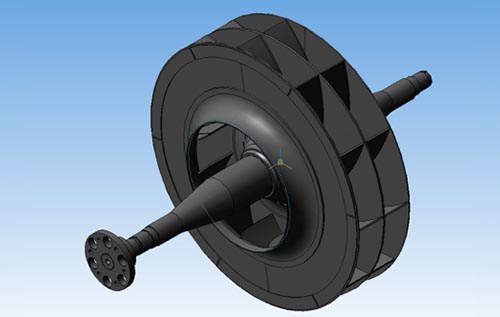

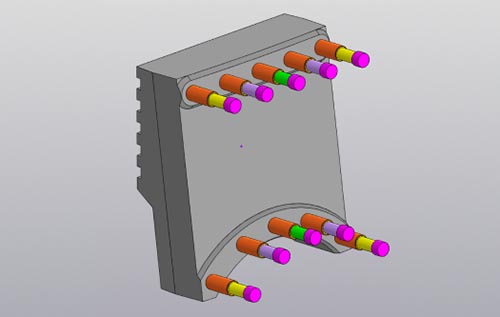

Some types of products, 3D models, design documentation:

Exhauster No. 5. Rotor 9000+ (Venti Oelde)

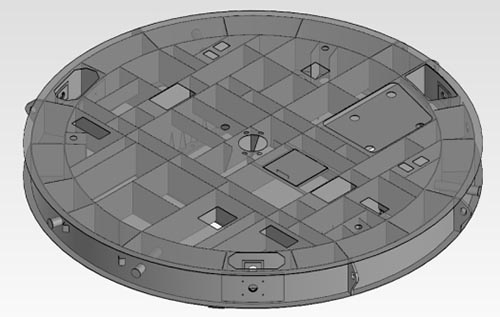

Cast iron stave

Pneumatic hammer

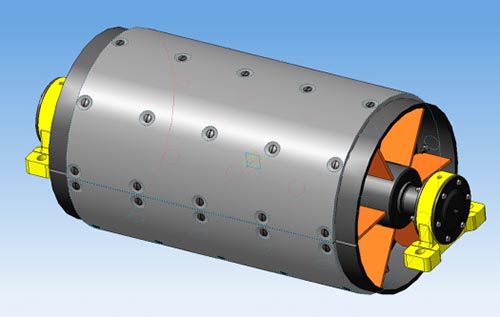

Conveyor drum

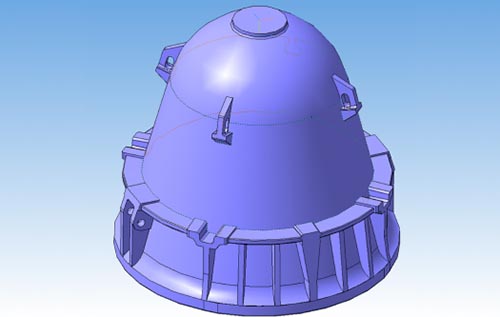

Slag pot

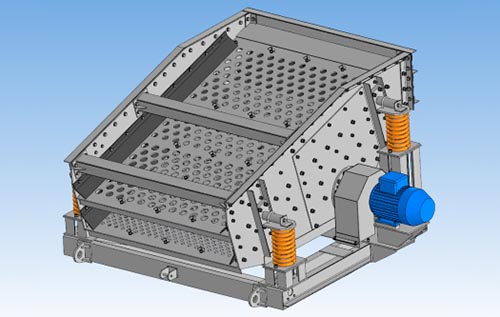

Screeners GST 62B

The screeners of coke

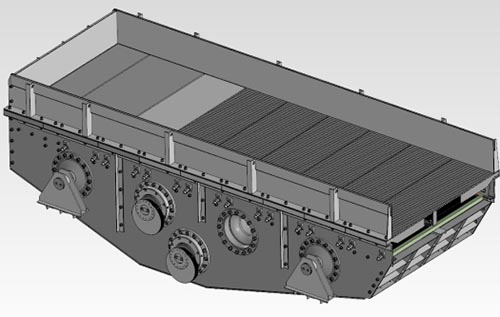

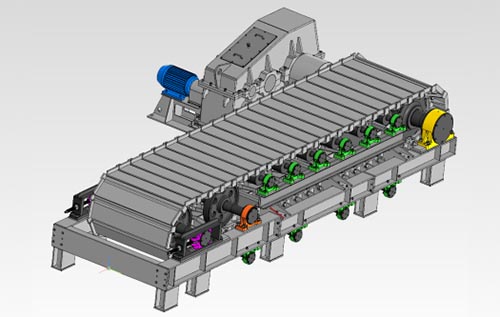

Plate feeder PP-2-15-60

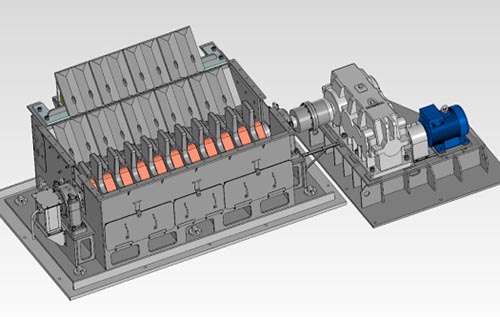

Single-roll grinder

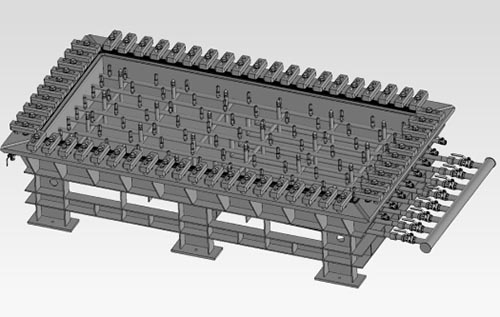

Cooling table

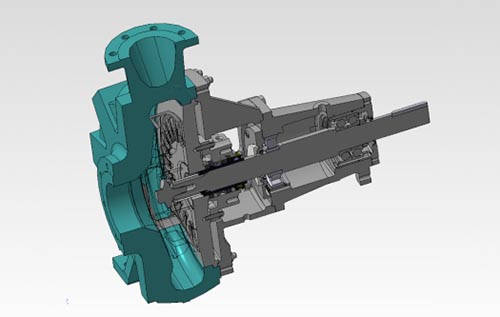

Quencher pump

The rotating frame

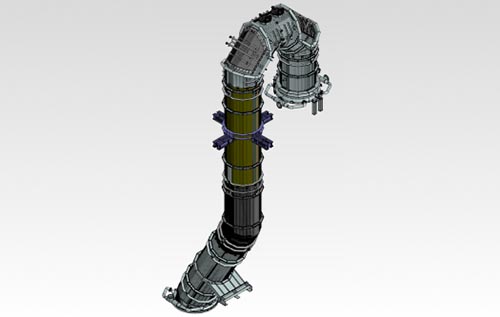

Gas-cleaning installation. Water cooling of converter gases

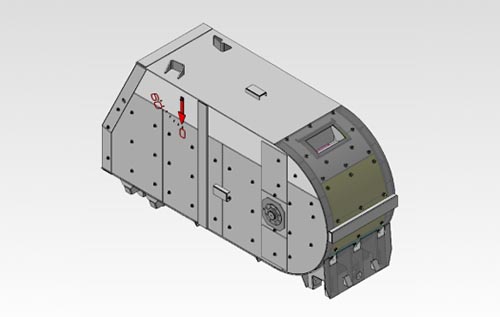

SDP-13.5-80 main lift skip

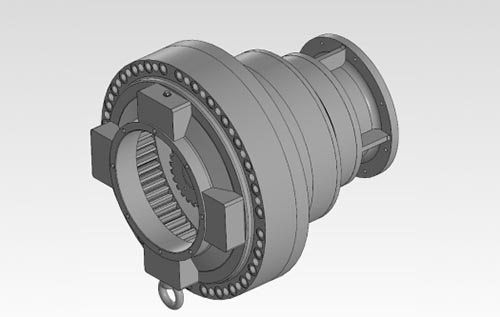

MPZ-760F2B-181,2-30/4-5A225M8 U2 planetary Motor-reductor

Closed coal warehouse. Silage watering can

Hydraulic cylinder for lifting consoles

Installation of flow sensors

Blast furnace loading device

Summary window

Gearbox