Our equipment

LLC “CMP” has equipment for casting, manufacturing of metal structures, cutting, heat treatment, etc.

Foundry equipment includes:

- electric arc heating steel melting furnaces of constant current with a capacity of 1, 3, 6 tons

- electric arc heating steel melting furnaces of constant current with a capacity of 5, 12 and 25 tons

- thermal furnaces with floor area from 11 to 63 m²

- induction crucible furnaces ITPE-1.0/0.8 TP

Forging and stamping equipment:

- a steam-air forging hammer with a mass of falling parts of 7,250 kg

- press-scissors with an effort of 1000 tons

- horizontal forging machine with a nominal force of 630 tons

Equipment for the production of metal structures:

- FACCINI three-roll sheet bending machine for bending a sheet with a thickness of 110 mm and a width of 3050 mm, minimum bending radius of 1080 mm

- ESAB CNC welding complex (automatic welding under a flux layer of beams up to 3 m high and up to 15 m long, cylindrical and conical beams up to 6 m in diameter and up to 8 m long)

- single-crank and hydraulic presses with a force of 400 tons

- crank scissors for mechanical cutting of sheets up to 32 mm thick

- CNC machines for oxygen and plasma metal cutting up to 240 mm thick

- cutting plasma installation JANTAR-2 2500/6000 (manufacturer in POLAND)

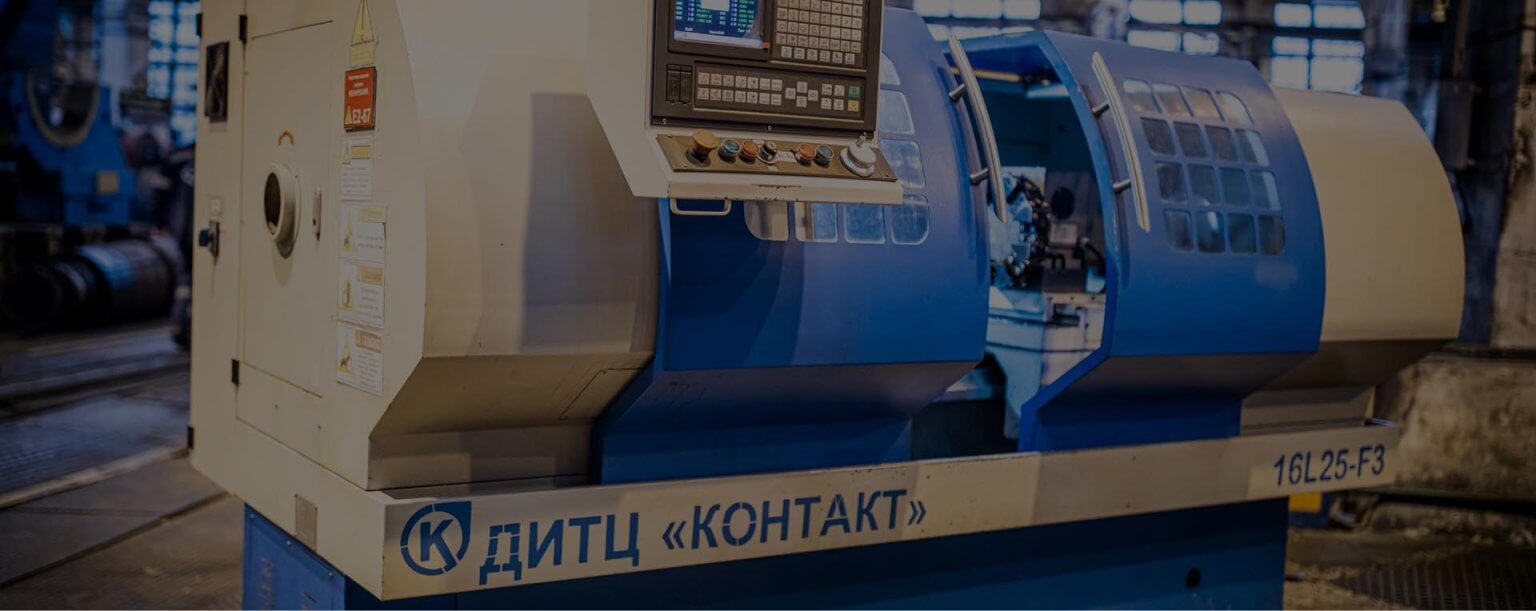

Equipment for mechanical processing:

- a lathe-carousel machine with a plan diameter of 7,100 mm, a maximum turning diameter of 8,000 mm, a height of the processed part up to 5,000 mm, and a maximum weight of the processed part up to 50 tons

- screw-turning machine with a center height of 1250 mm and a distance between centers of 10,000 mm

- lathe and screw-cutting machine with a center height of 730 mm and a distance between centers of 16100 mm

- lathe and screw-cutting machine with a center height of 1700 mm and a distance between centers of 12500 mm

- a horizontal boring machine with a spindle diameter of 220 mm

- gear –hobbing machines for processing gear wheels with a module of up to 75 mm (finger modular milling cutter) and crowns with a diameter of up to 5.0 m (8.0 m)

- a longitudinal milling machine with a working table size of 10.3 m by 2.5 m and a maximum weight of the processed part of 50 tons

- a special roller welding machine for welding the rolls of crimping machines with a diameter of up to 1.4 m, a length of up to 6.5 m and a weight of up to 40 tons