Our departments

The Mold Production shop was founded in 1954.

The purpose of the workshop of production casting molds is to provide replacement equipment (casting molds and pallets) to steel production shops.

- formative;

- mixture preparation;

- casting and pouring;

- felling;

- mechanical service;

- energy service;

- electric service.

Shaped steel foundry workshop was founded in 1970.

The main purpose is the production of shaped steel castings.

- model;

- mixture preparation;

- rod production;

- manual forming;

- machine forming and HTS, mold casting;

- smelting of electric steel in electric furnaces;

- fireproof;

- thermal cutting;

- mechanical service;

- energy service;

- electric service.

The main products: crusher armors, grinding balls, slag pots, backfilling devices of blast furnaces, cast iron staves of blast furnaces, excavator bucket walls, wheels, screen plates, grab jaws, bandages, half crowns.

The cast iron foundry workshop was founded in 1934.

The main purpose is the production of cast iron and non-ferrous castings.

CIFW provides the enterprise with cast iron and non-ferrous castings, replacement equipment and other spare parts

The material and technical base of the workshop consists of the following equipment:

induction furnaces, electric furnaces, drying drums, lifting cranes and machines, metal-working and wood-working machines, mixing runners, electric carts, conveyors, etc.

- model;

- mixture preparation;

- production of cast iron and special alloys;

- forming and punching;

- rod production;

- stumps;

- melting of metals and alloys;

- electric service;

- mechanical service.

Repair and mechanical workshop No. 1 was founded in 1933.

RMW No. 1 specializes in the manufacture of spare parts and repair of units and aggregates of equipment for agglomerationing, blast furnacing, convertering, refractory-lime, stamp-works, rolling shops. Restoration and strengthening of the surfaces of parts is also carried out in the workshop with the help of building-up on surfacing installations and heat treatment.

In the shop are also manufactured and repaired all crane equipment of metallurgical enterprises.

Repair and mechanical shop No. 1 has a forging section, which produces forgings and stampings from 2 kg to 7 tons.

RMW No. 1 is equipped with electric bridge cranes with a load capacity of up to 50 tons, self-propelled electric trolleys, thermal electric furnaces, machine park, forging and pressing equipment.

- blacksmith shop;

- universal machines;

- unique machines;

- repair and assembly;

- riveting;

- tin alloys pouring station;

- instrumental;

- thermal;

- production preparation area.

The main products of the workshop: forgings, stampings, gear wheels, sprockets, grabs, cones of backfilling devices of blast furnaces, rotors of agloexhausters, ladles of iron carriers, reducers, cannons of blast furnaces, crusher beds, loading and unloading end walls for ore beneficiation factories, crane wheels, crane rope drums, armors for crushers, worm shafts, crowns, bevel gears with an involute tooth, fans and toothed crowns.

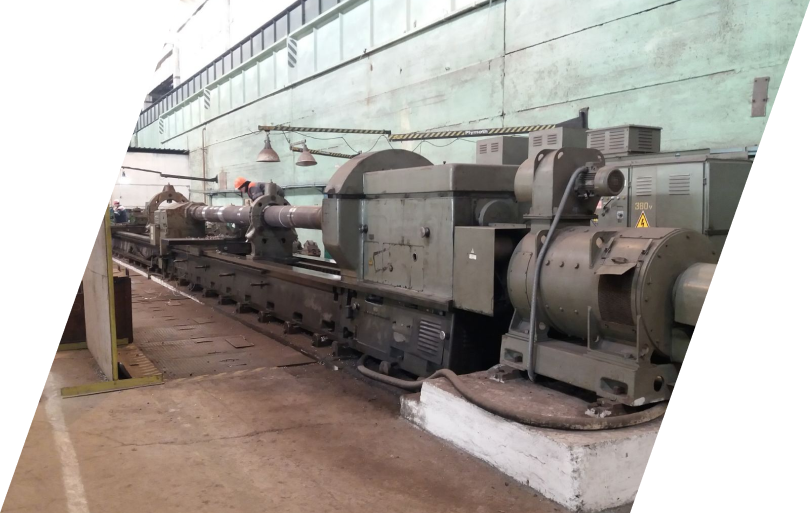

Repair and mechanical workshop No.2 was founded in 1968.

The workshop is equipped with unique equipment that allows processing parts with a diameter of up to 5 m, a length of up to 16 m and a weight of up to 50 tons. The main task of the workshop is the fulfillment of orders for the manufacture of replacement equipment, spare parts, repair of units and aggregates of crimping, rolling redistribution of metallurgical production, manufacture of spare parts and repair of mining and beneficiation equipment.

- area of unique machines;

- station of universal machines;

- department for maintenance and repair of mechanical equipment;

- electrical equipment maintenance and repair station;

- production preparation station;

- section of CNC machine tools;

- repair and assembly station;

- instrumental station.

Repair and assembly workshop No. 3 was founded in 1979.

The main purpose is the manufacturing of air nozzles for blast furnaces, the manufacturing and repair of the Cone boot devices(CBD) tray, the repair of Dy2000 hot blow valves, the manufacturing and repair of skips, the manufacturing of rods for the filling devices of blast furnaces, the manufacturing of coils for refrigerating plates, performs surfacing of bimetallic sheets ẟ10÷20 mm. size 1400×2900, repair by surfacing parts weighing up to 32 tons, production of rubber products. Also it has a railway connection.

The main products of RAW No. 3: hot and cold agglomerate booms for sinter plants, coke and agglomerate booms for blast furnaces, coke crushers, repair of iron ore and steel casting buckets, excavator buckets, grabs, traverses with a load capacity of 200 tons.

The metal construction shop was founded in 1938.

The main purpose is the manufacture and repair of metal structures.

The workshop is equipped with electric overhead cranes with a load capacity of 5 to 50 tons, gantry cranes, thermal and plasma cutting machines, a fleet of guillotine shears, which allow cutting of sheet metal from 2 mm to 32 mm thick and profiled metal; a fleet of sheet-bending machines for the production of cylindrical blanks of metal structures, the possibility of bending a sheet up to 110 mm to a width of 1.5 m; hydraulic presses for corrective and bending technological operations; crank and perforation presses for the production of stamping works, electric welding equipment that allows performing manual arc welding, mechanized in a mixture of gases, automatic under a flux layer, robotic welding; as well as equipment for heat treatment of welding seams on cylindrical parts of large sizes.

- rolled metal warehouse with the possibility of railway transport access;

- production preparation;

- procurement station;

- assembly and welding station;

- maintenance and repair of mechanical equipment;

- maintenance and repair of electrical equipment.

The products of MCS are welded metal structures and parts for current and capital repairs of equipment. The nomenclature of products manufactured by MCS consists of metal structures and assemblies weighing from 1 kg to 50 tons.